Pre- and post-comparison between two identical buildings

Downloads

DOI:

https://doi.org/10.47982/jfde.2023.1.01Published

Issue

Section

License

Copyright (c) 2023 Nicola Callegaro, Rossano Albatici

This work is licensed under a Creative Commons Attribution 4.0 International License.

Authors or their institutions retain copyright to their publications without restrictions.

How to Cite

Keywords:

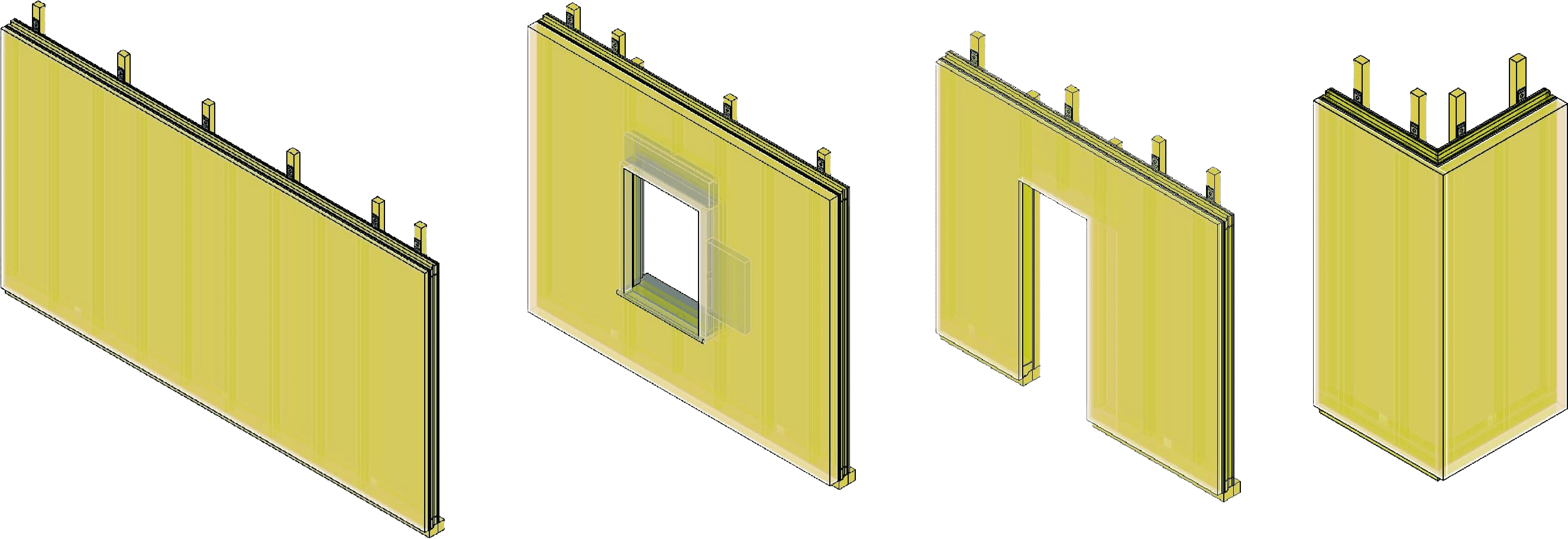

Building façade retrofitting, Timber-based façades, hygrothermal performance, Building renovation, prefabricated constructionAbstract

The introduction of prefabrication into the building façade retrofit market is still difficult due to many financial, economic, and social constraints, as well as technical and performance requirements that differ from those of new construction. The technical feasibility, construction details, and actual comfort and energy-saving benefits provided by the installation of prefabricated façade modules are still being investigated, as is one goal of the specific case study presented here. The Renew-Wall project aims to create a new modular, timber-based, non-intrusive system for retrofitting buildings, developing a series of significant and fully customisable innovations compared to currently available solutions. This paper describes the main properties of the designed prefabricated façade system, with a focus on its energy and thermo-hygrometric performances. Simulation and laboratory tests are compared with an experimental analysis conducted on two identical mock-up buildings (test cells) during a two-year monitoring campaign in which only one of the two test cells was retrofitted. The results show simulated average annual energy savings of 67%, perfectly in line with what was measured on-site. The prefabricated façade system also demonstrates efficient vapour release and a reduced risk of mould and fungus attack.

References

Alfano, F. R. d’Ambrosio, & de Santoli, L. (2017). Energy Efficiency and HVAC Systems in Existing and Historical Buildings. In G. Franco & A. Magrini (Eds.), Historical Buildings and Energy (pp. 45–53). Springer International Publishing. https://doi.org/10.1007/978-3-319-52615-7_3 DOI: https://doi.org/10.1007/978-3-319-52615-7_3

Arnesano, M., Bueno, B., Pracucci, A., Magnagni, S., Casadei, O., & Revel, G. M. (2019, July). Sensors and control solutions for Smart-IoT façade modules. 2019 IEEE International Symposium on Measurements and Networking. https://doi.org/10.1109/IWMN.2019.8805024 DOI: https://doi.org/10.1109/IWMN.2019.8805024

ASHRAE Guideline 14, 2014 (2014). www.ashrae.org/technology.

Azcarate-Aguerre, J. F., Heijer, A. C. D., & Klein, T. (2018). Integrated Facades as a Product-Service System: Business process innovation to accelerate integral product implementation. Journal of Facade Design and Engineering, 6(1), 41–56. https://doi.org/10.7480/jfde.2018.1.1840

Bagarić, M., Banjad Pečur, I., & Milovanović, B. (2020). Hygrothermal performance of ventilated prefabricated sandwich wall panel from recycled construction and demolition waste – A case study. Energy and Buildings, 206, 109573. https://doi.org/10.1016/j.enbuild.2019.109573 DOI: https://doi.org/10.1016/j.enbuild.2019.109573

Callegari, G., Spinelli, A., Bianco, L., Serra, V., & Fantucci, S. (2015). NATURWALL©—A Solar Timber Façade System for Building Refurbishment: Optimization Process through in Field Measurements. Energy Procedia, 78, 291–296. https://doi.org/10.1016/J.EGYPRO.2015.11.641 DOI: https://doi.org/10.1016/j.egypro.2015.11.641

Callegaro, N., & Albatici, R. (2021). Progettazione, gestione e analisi dati per il monitoraggio energetico-ambientale degli edifici: Problemi e opportunità. In EdicomEdizioni (Ed.), Design and construction—Tradition and innovation in the practice of architecture, Monfalcone (Gorizia): EdicomEdizioni. Proceedings of: ColloquiATe2021, Salerno (Italia), 8-11 settembre 2021 (pp. 1127–1141).

Capeluto, G. (2019). Adaptability in envelope energy retrofits through addition of intelligence features. Architectural Science Review, 62(3), 216–229. https://doi.org/10.1080/00038628.2019.1574707 DOI: https://doi.org/10.1080/00038628.2019.1574707

Capener, C.-M., Burke, S., Le Roux, S., & Ott, S. (2014). Hygrothermal Performance of TES Energy Façade at two European residential building demonstrations: Comparison between Field Measurements and Simulations. NSB 2014 10th Nordic Symposium on Building Physics, Lund, Sweden, 15-19 June 2014.

Cattarin, G., Causone, F., Kindinis, A., & Pagliano, L. (2016). Outdoor test cells for building envelope experimental characterisation—A literature review. Renewable and Sustainable Energy Reviews, 54, 606–625. https://doi.org/10.1016/j.rser.2015.10.012 DOI: https://doi.org/10.1016/j.rser.2015.10.012

Dannapfel, V., Osterhage, T., Klein, M., Streblow, R., Vontein, M., Müller, D., & Kuhnhenne, M. (2019). The PLUG-N-HARVEST façade: A second skin with active and passive components. Journal of Facade Design and Engineering, 7(1), 101–114. https://doi.org/10.7480/JFDE.2019.1.2772

De Masi, R. F., Ruggiero, S., & Vanoli, G. P. (2021). Hygro-thermal performance of an opaque ventilated façade with recycled materials during wintertime. Energy and Buildings, 245, 110994. https://doi.org/10.1016/j.enbuild.2021.110994 DOI: https://doi.org/10.1016/j.enbuild.2021.110994

Dermentzis, G., Ochs, F., Siegele, D., & Feist, W. (2018). Renovation with an innovative compact heating and ventilation system integrated into the façade – An in-situ monitoring case study. Energy and Buildings, 165, 451–463. https://doi.org/10.1016/j.enbuild.2017.12.054 DOI: https://doi.org/10.1016/j.enbuild.2017.12.054

D’Oca, S., Ferrante, A., Ferrer, C., Pernetti, R., Gralka, A., Sebastian, R., & Veld, P. op t. (2018). Technical, Financial, and Social Barriers and Challenges in Deep Building Renovation: Integration of Lessons Learned from the H2020 Cluster Projects. Buildings, 8(12), 174. https://doi.org/10.3390/BUILDINGS8120174 DOI: https://doi.org/10.3390/buildings8120174

D’Oca, S., Op ’t Veld, P., & Tisov, A. (2017). D2.1: Report on the State of the Art of Deep Renovation to nZEB and Pre-Fab System in EU - HORIZON 2020 project ProGETone. EC Grant Agreement No. 723747 (p. 87).

Evola, G., Costanzo, V., Urso, A., Tardo, C., & Margani, G. (2022). Energy performance of a prefabricated timber-based retrofit solution applied to a pilot building in Southern Europe. Building and Environment, 222, 109442. https://doi.org/10.1016/j.buildenv.2022.109442 DOI: https://doi.org/10.1016/j.buildenv.2022.109442

Goia, F., Schlemminger, C., & Gustavsen, A. (2017). The ZEB Test Cell Laboratory. A facility for characterization of building envelope systems under real outdoor conditions. Energy Procedia, 132, 531–536. https://doi.org/10.1016/J.EGYPRO.2017.09.718 DOI: https://doi.org/10.1016/j.egypro.2017.09.718

Höfler, K., Knotzer, A., & Venus, D. (2015). Renovation concepts for net zero energy buildings. Advances in Building Energy Research, 9(1), 107–119. https://doi.org/10.1080/17512549.2014.941007 DOI: https://doi.org/10.1080/17512549.2014.941007

International Association for Science and Technology of Building Maintenance and Monuments Preservation. (2014). Simulation of heat and moisture transfer - WTA Guideline 6-2-14. https://www.baufachinformation.de/simulation-of-heat-and-moisture-transfer/mb/247749

Kasperzyk, C., Kim, M.-K., & Brilakis, I. (2017). Automated re-prefabrication system for buildings using robotics. Automation in Construction, 83, 184–195. https://doi.org/10.1016/j.autcon.2017.08.002 DOI: https://doi.org/10.1016/j.autcon.2017.08.002

Li, J., Lu, S., Wang, W., Huang, J., Chen, X., & Wang, J. (2018). Design and Climate-Responsiveness Performance Evaluation of an Integrated Envelope for Modular Prefabricated Buildings. Advances in Materials Science and Engineering, 2018, e8082368. https://doi.org/10.1155/2018/8082368 DOI: https://doi.org/10.1155/2018/8082368

Martinez, A., & Choi, J.-H. (2018). Analysis of energy impacts of facade-inclusive retrofit strategies, compared to system-only retrofits using regression models. Energy and Buildings, 158, 261–267. https://doi.org/https://doi.org/10.1016/j.enbuild.2017.09.093 DOI: https://doi.org/10.1016/j.enbuild.2017.09.093

Paiho, S., Seppä, I. P., & Jimenez, C. (2015). An energetic analysis of a multifunctional façade system for energy efficient retrofitting of residential buildings in cold climates of Finland and Russia. Sustainable Cities and Society, 15, 75–85. https://doi.org/10.1016/j.scs.2014.12.005 DOI: https://doi.org/10.1016/j.scs.2014.12.005

Pihelo, P., & Kalamees, T. (2021). Commissioning of moisture safety of nZEB renovation with prefabricated timber frame insulation wall elements. Wood Material Science & Engineering, 16(2), 110–117. https://doi.org/10.1080/17480272.2019.1635206 DOI: https://doi.org/10.1080/17480272.2019.1635206

Pittau, F., Malighetti, L. E., Iannaccone, G., & Masera, G. (2017). Prefabrication as Large-scale Efficient Strategy for the Energy Retrofit of the Housing Stock: An Italian Case Study. Procedia Engineering, 180, 1160–1169. https://doi.org/10.1016/J.PROENG.2017.04.276 DOI: https://doi.org/10.1016/j.proeng.2017.04.276

Richard, R. B. (2005). Industrialised building systems: Reproduction before automation and robotics. Automation in Construction, 14(4), 442–451. https://doi.org/10.1016/J.AUTCON.2004.09.009 DOI: https://doi.org/10.1016/j.autcon.2004.09.009

Salvalai, G., Sesana, M. M., & Iannaccone, G. (2017). Deep renovation of multi-storey multi-owner existing residential buildings: A pilot case study in Italy. Energy and Buildings, 148, 23–36. https://doi.org/10.1016/j.enbuild.2017.05.011 DOI: https://doi.org/10.1016/j.enbuild.2017.05.011

Shahpari, M., Saradj, F. M., Pishvaee, M. S., & Piri, S. (2020). Assessing the productivity of prefabricated and in-situ construction systems using hybrid multi-criteria decision making method. Journal of Building Engineering, 27, 100979. https://doi.org/10.1016/j.jobe.2019.100979 DOI: https://doi.org/10.1016/j.jobe.2019.100979

Shnapp, S., Sitjà, R., & Laustsen, J. (2013). What is a deep renovation definition? Global Buildings Performance Network—Technical Report. GBPN. https://www.gbpn.org/wp-content/uploads/2021/06/08.DR_TechRep.low_.pdf

Silva, P. C. P., Almeida, M., Bragança, L., & Mesquita, V. (2013). Development of prefabricated retrofit module towards nearly zero energy buildings. Energy and Buildings, 56, 115–125. https://doi.org/10.1016/j.enbuild.2012.09.034 DOI: https://doi.org/10.1016/j.enbuild.2012.09.034

Teng, Y., Li, K., Pan, W., & Ng, T. (2018). Reducing building life cycle carbon emissions through prefabrication: Evidence from and gaps in empirical studies. Building and Environment, 132, 125–136. https://doi.org/10.1016/j.buildenv.2018.01.026 DOI: https://doi.org/10.1016/j.buildenv.2018.01.026

Torres, J., Garay-Martinez, R., Oregi, X., Torrens-Galdiz, J. I., Uriarte-Arrien, A., Pracucci, A., Casadei, O., Magnani, S., Arroyo, N., & Cea, A. M. (2021). Plug and Play Modular Façade Construction System for Renovation for Residential Buildings. Buildings, 11(9), 419. https://doi.org/10.3390/BUILDINGS11090419 DOI: https://doi.org/10.3390/buildings11090419

Zanni, J., Cademartori, S., Marini, A., Belleri, A., Passoni, C., Giuriani, E., Riva, P., Angi, B., Brumana, G., & Marchetti, A. L. (2021). Integrated Deep Renovation of Existing Buildings with Prefabricated Shell Exoskeleton. Sustainability, 13(20), 11287. https://doi.org/10.3390/SU132011287 DOI: https://doi.org/10.3390/su132011287