Downloads

DOI:

https://doi.org/10.47982/jfde.2024.350Published

Issue

Section

License

Copyright (c) 2026 Fady Abdelaziz, Samuel Esses, Kostas Grigoriadis

This work is licensed under a Creative Commons Attribution 4.0 International License.

Authors or their institutions retain copyright to their publications without restrictions.

How to Cite

Keywords:

Computational Design, Multi-property Façade Design, Multi-objective optimisation, Daylight PerformanceAbstract

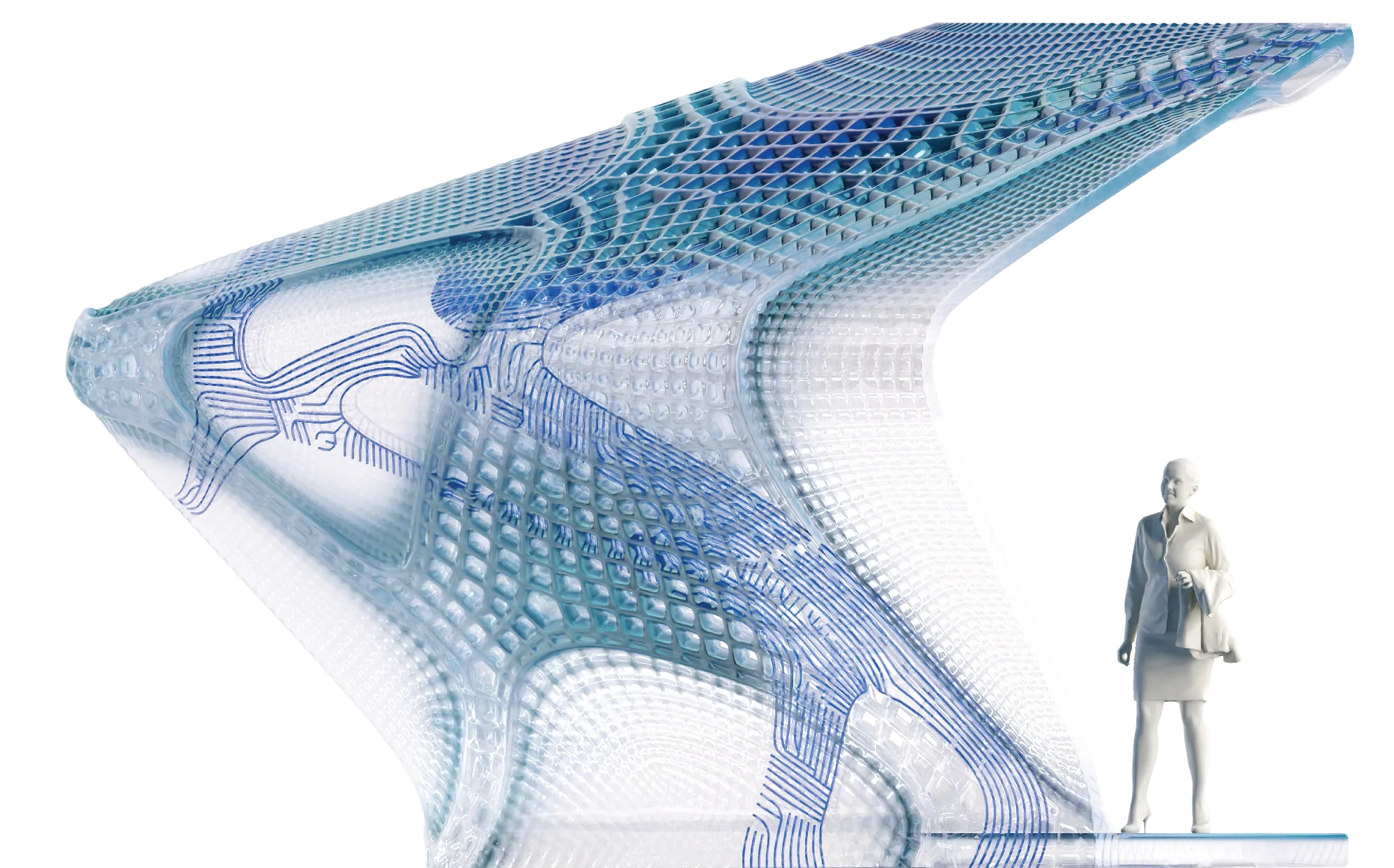

Traditional fabrication methods for plastic building panels, such as moulding and extrusion, have recently been advanced by large-scale robotic 3D printing (LSR3DP), enabling mass customisation and the production of complex architectural geometries. While existing research on LSR3DP has primarily focused on single-material printing, the exploration of multi-material or multi-property applications remains limited, especially at full architectural scale. This study addresses this gap by developing a performance-driven digital workflow for PETG-based façades that integrates structural efficiency with solar-responsive transmittance gradients. A multiobjective optimisation process using the Non-dominated Sorting Genetic Algorithm II (NSGA-II) generated 16 optimal façade geometries across four orientations (north, east, south, west), achieving up to 14% reduction in summer solar radiation and 26% increase in winter solar gain compared to a conventional vertical façade, while minimising structural displacement. The optimal south-facing solution was selected for detailed daylight performance assessment. A procedural gradient generation workflow was developed to discretise solar-based transmittance values across varying mesh densities and gradient resolutions. The best-performing variable transmittance configuration achieved 46.24% Useful Daylight Illuminance (UDI-a) and 69.21% spatial Daylight Autonomy (sDA), representing a 25.94% improvement in UDI-a over a conventional uniform-transmittance curtain wall. This integrated approach demonstrates LSR3DP’s potential to produce unified, materially expressive façades that embed environmental performance directly into form and material logic, eliminating reliance on mechanical shading systems.

References

BS EN 17037:2018. (2021). BSI. https://knowledge.bsigroup.com/products/daylight-in-buildings-1

Bollinger, K., Grohmann, M., & Tessman, O. (2010). Form follows performance. In Symposium on Simulation for Architecture and Urban Design.

Castañeda, E., Lauret, B., Lirola, J. M., & Ovando, G. (2015). Free-form architectural envelopes: Digital processes opportunities of industrial production at a reasonable price. Journal of Façade Design and Engineering, 3(1), 1–13. https://doi.org/10.3233/fde-150031 DOI: https://doi.org/10.3233/FDE-150031

Cheibas, I., Gamote, R. P., Lloret-Fritschi, E., Arnold, K., Luible, A., Gramazio, F., & Kohler, M. (2024). 3D printing of a multi-performative building envelope: Assessment of air permeability, water tightness, wind loads, and impact resistance. Journal of Building Engineering, 98. https://doi.org/10.1016/j.jobe.2024.111251 DOI: https://doi.org/10.1016/j.jobe.2024.111251

Cheibas, I., Piccioni, V., Lloret-Fritschi, E., Leschok, M., Schlüter, A., Dilllenburger, B., Gramazio, F., & Kohler, M. (2023). Light Distribution in 3D-Printed Thermoplastics. 3D Printing and Additive Manufacturing, 10(6), 1164–1177. https://doi.org/10.1089/3dp.2023.0050 DOI: https://doi.org/10.1089/3dp.2023.0050

Department for Education. (2022). School Output Specification Technical Annex 2E: Daylight and Electric Lighting. https://assets.publishing.service.gov.uk/media/637e13508fa8f56eb1a0ad14/GDB_Annex_2E_DaylightAndElectricLighting-A-C11.pdf

Education Funding Agency. (2014). Baseline Design-Daylight Strategy. https://assets.publishing.service.gov.uk/media/5b3b6a27ed915d33ced545ca/Baseline_designs_daylight_strategy_Dec_2014.pdf

Engelsmann, S., Spalding, V., & Peters, S. (2010). Plastics. https://doi.org/10.1515/9783034611947 DOI: https://doi.org/10.1515/9783034611947

Fan, Z., Liu, M., & Tang, S. (2022). A multiobjective optimization design method for gymnasium façade shading ratio integrating energy load and daylight comfort. Building and Environment, 207. https://doi.org/10.1016/j.buildenv.2021.108527 DOI: https://doi.org/10.1016/j.buildenv.2021.108527

Grigoriadis, K., & Lee, G. (2024). 3D printing and material extrusion in architecture: Construction and design manuals. DOM Publishers.

Grigoriadis, K. (2018). The current state of autography. International Journal of Rapid Manufacturing, 7 (2/3), 277–294. https://doi.org/10.1504/IJRAPIDM.2018.092902 DOI: https://doi.org/10.1504/IJRAPIDM.2018.092902

Grigoriadis, K. (2019). Computational blends: The epistemology of designing with functionally graded materials. Journal of Architecture, 24(2), 160–192. https://doi.org/10.1080/13602365.2019.1578074 DOI: https://doi.org/10.1080/13602365.2019.1578074

Hwang, CL., Yoon, K. (1981). Methods for Multiple Attribute Decision Making. In: Multiple Attribute Decision Making. Lecture Notes in Economics and Mathematical Systems, vol 186. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-642-48318-9_3 DOI: https://doi.org/10.1007/978-3-642-48318-9

K. Deb, A. Pratap, S. Agarwal and T. Meyarivan, “A fast and elitist multiobjective genetic algorithm: NSGA-II,” in IEEE Transactions on Evolutionary Computation, vol. 6, no. 2, pp. 182-197, April 2002, doi: 10.1109/4235.996017. DOI: https://doi.org/10.1109/4235.996017

Kwon, H., Kyttas, T., Eichenhofer, M., & Dillenburger, B. (2019). Digital Composites: Robotic 3D Printing of Continuous Carbon Fiber-Reinforced Plastics for Functionally-Graded Building Components. Robotic Fabrication in Architecture, Art and Design 2018: Foreword by Sigrid Brell-Çokcan and Johannes Braumann, Association for Robots in Architecture, 363–376. https://doi.org/10.1007/978-3-319-92294-2_28 DOI: https://doi.org/10.1007/978-3-319-92294-2_28

Lin, C. H., & Tsay, Y. S. (2024). A practical decision process for building façade performance optimization by integrating machine learning and evolutionary algorithms. Journal of Asian Architecture and Building Engineering, 23(2), 740–753. https://doi.org/10.1080/13467581.2023.2244564 DOI: https://doi.org/10.1080/13467581.2023.2244564

Milano, F., Gamote, R. P., Olivo, N. E., Piccioni, V., Chen, P. Y., Gallagher, C., Schlueter, A., Dillenburger, B., Luible, A., Gramazio, F., & Kohler, M. (2024). Integration of a 3D-Printed Façade Unit in a Curtain Wall System: Prototyping and Assessment. Journal of Façade Design and Engineering, 12(1), 9–28. https://doi.org/10.47982/jfde.2024.325 DOI: https://doi.org/10.47982/jfde.2024.325

Mungenast, M. (2017). 3d-Printed Low-tech Future Façades – Development of 3d-printed Functional-Geometries for Building Envelopes. PowerSkin Conference Proceedings , 307–317.

Piccioni, V., Turrin, M., & Tenpierik, M. J. (2020). A Performance-Driven Approach for the Design of Cellular Geometries with Low Thermal Conductivity for Application in 3D-Printed Façade Components. Of the Symposium on Simulation for Architecture and Urban Design SimAUD.

Preisinger, C. (2013). Linking structure and parametric geometry. Architectural Design, 83(2), 110-113. https://doi.org/10.1002/ad.1564 DOI: https://doi.org/10.1002/ad.1564

Robert McNeel & Associates. (n.d.). Rhinoceros 3D [Computer software]. Retrieved November 21, 2025, from https://www.rhino3d.com/

Roudsari, M., & Ladybug Tools LLC. (n.d.). Ladybug Tools [Software & documentation]. Retrieved November 21, 2025, from https://www.ladybug.tools/

Rutten, D., & Robert McNeel & Associates. (n.d.). Grasshopper 3D [Visual programming environment]. Retrieved November 21, 2025, from https://www.grasshopper3d.com/

Quillet, A., & Rogan, D. (2022). Wonova: the future of façades? - Eckersley O’Callaghan. https://www.eocengineers.com/wonova-the-future-of-facades/

Sarakinioti, M. V., Turrin, M., Konstantinou, T., Tenpierik, M., & Knaack, U. (2018). Developing an integrated 3D-printed façade with complex geometries for active temperature control. Materials Today Communications, 15, 275–279. https://doi.org/10.1016/j.mtcomm.2018.02.027 DOI: https://doi.org/10.1016/j.mtcomm.2018.02.027

Shan, R., & Shi, T. (2016). Multiobjective optimization of building façade design strategies. In Proceedings of the 3rd Asia Conference of the International Building Performance Simulation Association (ASim 2016). IBPSA.

Showkatbakhsh, M., Makki, M., & Song, Y. (n.d.). Wallacei [Software plugin]. Retrieved August 1, 2025, from https://www.wallacei.com/

SideFX. (n.d.). (n.d.). Attribute Transfer. Retrieved July 27, 2025, from https://www.sidefx.com/docs/houdini/nodes/sop/attribtransfer.html

Taseva, Y., Eftekhar, N., Kwon, H., Leschok, M., & Dillenburger, B. (2020). LARGE-SCALE 3D PRINTING FOR FUNCTIONALLY-GRADED FAÇADE (Vol. 1). DOI: https://doi.org/10.52842/conf.caadria.2020.1.183

Tee, Y. L., Peng, C., Pille, P., Leary, M., & Tran, P. (2020). PolyJet 3D Printing of Composite Materials: Experimental and Modelling Approach. JOM, 72(3), 1105–1117. https://doi.org/10.1007/s11837-020-04014-w DOI: https://doi.org/10.1007/s11837-020-04014-w

Tenpierik, M., Turrin, M., Wattez, Y., Cosmatu, T., & Tsafou, S. (2018). View of Double Face 2.0: A lightweight translucent adaptable Trombe wall | SPOOL. https://spool.ac/index.php/spool/article/view/86/85

Vazquez, E., & Duarte, J. (2022). Exploring the Impact of Geometry and Fibre Arrangements on Daylight Control in Bistable Kinetic Shades. Journal of Façade Design and Engineering, 10(1). https://doi.org/10.47982/jfde.2022.1.03 DOI: https://doi.org/10.47982/jfde.2022.1.03

Wagiri, F., Shih, S. G., Harsono, K., & Wijaya, D. C. (2024). Multiobjective optimization of kinetic façade aperture ratios for daylight and solar radiation control. Journal of Building Physics, 47(4), 355–385. https://doi.org/10.1177/17442591231219793 DOI: https://doi.org/10.1177/17442591231219793

Yuan, P. F., Beh, H. S., Yang, X., Zhang, L., & Gao, T. (2022). Feasibility study of large-scale mass customization 3D printing framework system with a case study on Nanjing Happy Valley East Gate. Frontiers of Architectural Research, 11(4), 670–680. https://doi.org/10.1016/j.foar.2022.05.005 DOI: https://doi.org/10.1016/j.foar.2022.05.005