Downloads

DOI:

https://doi.org/10.7480/jfde.2017.1.1427Published

Issue

Section

License

Copyright (c) 2017 Roberto Naboni, Anja Kunic, Luca Breseghello, Ingrid Paoletti

This work is licensed under a Creative Commons Attribution 4.0 International License.

Authors or their institutions retain copyright to their publications without restrictions.

How to Cite

Keywords:

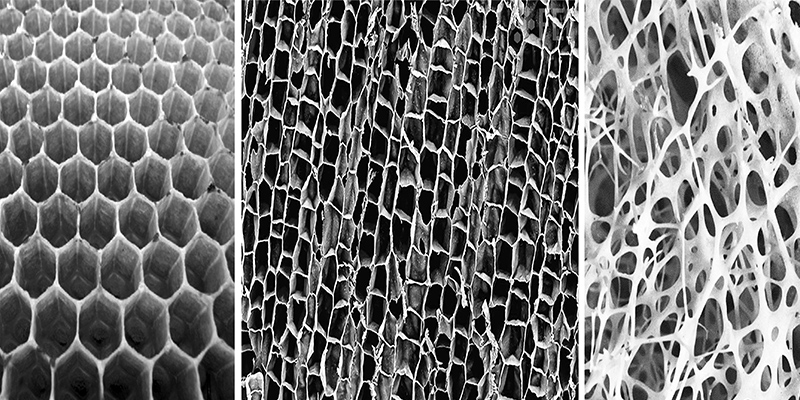

Cellular lattice, Skin System, Digital fabrication, Additive Manufacturing, Computational DesignAbstract

The last decades have been marked by a growing concern over scarcity of resources caused by the rapid industrialization of emerging economies as well as by the high material consumption at a global scale. These changing environmental conditions have inevitably created new challenges and demands for mediation of the interaction between the natural and the human-made environments. In response to these challenges, designers are currently moving away from conventional top-down design, towards a nature-inspired approach in search of the underlying principles of morphogenesis and materialization inherent to biological entities. Inscribed in this approach, this paper proposes an innovative design-to-fabrication workflow for the conception of nature-inspired load-responsive skin systems which integrates the use of computational tools, Additive Manufacturing, and material experiments with full-scale prototypes. The design phase employs custom algorithms to determine an optimal material distribution for free-form architectural shapes, given a specific loading condition. Through fabrication tests at different scales, the viability of a production system based on Fused Deposition Modelling is demonstrated. Subsequently, the realization of a final prototype of a load-responsive cellular envelope cladded with Fiber-Glass Reinforced Plastic is presented. Opportunities and current limitations of the approach and the emerging architectural system are critically discussed towards future developments.

References

Ashby, M.F. (2005). The properties of foams and lattices, Philosophical Transactions of the Royal Society, No.364, November 2005, pp. 15-30.

Ashby, M.F., Evans, A.G., Fleck, N.A., Hutchinson, J.W., Gibson, L.J. & Wadley, H. (2000). Metal foams - a design guide, Vol. 1, Butterworth-Heinemann.

Benyus, J. M. (2002). Biomimicry. Innovation inspired by nature, HarperCollins Publishers, NYS.

Gibson, L.J. (2005). Biomechanics of cellular solids, Journal of Biomechanics, No. 38, pp. 377-399.

Gibson, L.J. & Ashby, M.F. (1997). Cellular Solids: Structure and Properties, 2nd edition, Cambridge University Press, Cambridge.

Hensel, M. (2011). Performance-oriented Architecture and the Spatial and Material Organisation Complex -Rethinking the Definition, Role and Performative Capacity of the Spatial and Material Boundaries of the Built Environment, FORMAkademisk. In Hensel, M. (2013). AD Primer: Performance oriented Architecture, Rethinking Architectural Design and the Built Environment. John Wiley & Sons, London.

Hooke, R. C. (1665). Micrographia: or Some Physiological Descriptions of Miniature Bodies Made by Magnifying Glasses. London, England: Jo. Martyn, and Ja. Allestree.

Kim, J.W., Kim, H.S. & Lee, D.G. (2012). Tensile Strength of Glass Fiber-reinforced Plastic by Fiber Orientation and Fiber Content Variations, International Journal of Modern Physics: Conference Series, Vol. 6, World Scientific, Singapore.

Naboni, R. & Paoletti, I. (2015). Advanced customization in architectural design and construction, 1st edition, Springer Verlag, 2015.

Turner, J.S. (2012) Evolutionary architecture. Some perspectives from biological design, In AD, Architectural Design: Material Computation, No. 216, March/April 2012, pp. 28-33.