Downloads

DOI:

https://doi.org/10.7480/jfde.2017.1.1526Published

Issue

Section

License

Copyright (c) 2017 Prof. Dipl.-Ing Claudia Lüling, Dipl.-Ing. Iva Richter

This work is licensed under a Creative Commons Attribution 4.0 International License.

Authors or their institutions retain copyright to their publications without restrictions.

How to Cite

Keywords:

lightweight design, prefabricated textile envelope, foamed spacer fabrics, FabricFoamAbstract

“Architecture Fully Fashioned” is about lightweight design and new textile based building skins. Fully fashioned refers to a textile production technology wherein all parts of a piece of cloth are produced in one integrated production process, ready to wear the moment they leave the machine. Fully fashioned powerskin in an architectural sense implies a light, highly prefabricated textile envelope with minimum needs of installation work on the building site.

To develop these new textile powerskins, experimental student works and applied research projects at Frankfurt University of Applied Science investigate the potential of the combination of textile technologies with foaming technologies. This paper focuses on so called spacer fabrics and a research project called 3dTEX and founded by Zukunf Bau, where wall elements from foamed spacer fabrics presently are under development. The aim of the paper is to present 3dTEX within the context of the accompanying experimental student design works and to show the so far achieved results for a prefabricated, lightweight, self supporting and highly insulated foamed textile skin, with reduced needs of installation work on the building site. This has been achieved by using the spacer fabric as lost formwork and using 3d-textile technologies, so as woven or warp-knitted spacer fabrics, in order to receive complex geometrical sandwich-like textiles. Together with the foam they become FabricFoam©. The new selfsupporting building elements not only offer possibilities for complex architectonical geometries including loadbearing structures, but also a wide range of surface designs in terms of structures, colours and additional functionalities. The focus of 3dTEX is on the development of appropriate textile geometries for one- ore two-layer textile elements, depending on the choosen textile technologies. Foamed, they become lightweight, insulated elements, where the two layer textile can even be transformed into a ready-made, rear-ventilated, insulated wall element made from gradient fibre and foam material, able to absorb tensile and compressive forces at the same time.

The challenge for 3dTEX is to close the knowledge gap about what kind of textile technology can produce the envisioned textile geometry with which kind of fibre material. Further, 3dTEX research is about the appropriate, possibly in-situ, foaming technology and foam material, so that fibre and foam materials match as an aesthetic architectural element and in terms of mechanical and building physics as well as in terms of grey energy and recycling aspects.

References

Issey Miyake I., Fujiwara D., & Kries M. (2001) A-POC MAKING Vitra Design Museum

Texdata International (2015) 13th Techtextil Innovation Award 2015 honours eight outstanding developments Techtextil Innovation Award 2015 Kategorie “New Composite” http://www.texdata.com/news/Techtextil2015/8672.13th-Techtextil-Innovation-Award-2015-honours-eight-outstanding-developments.html

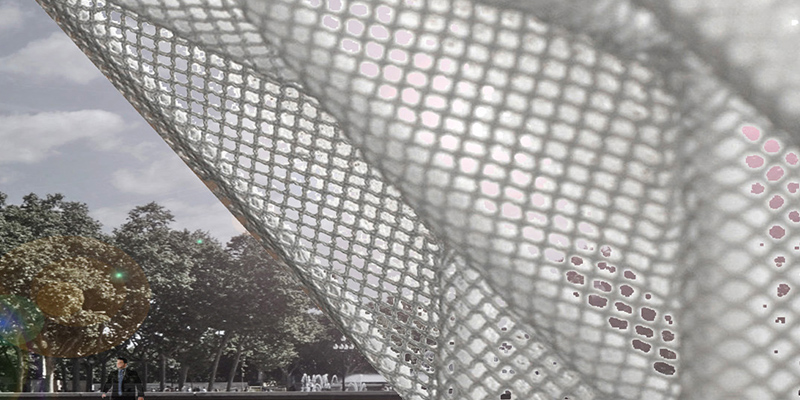

SpacerFabric Pavillon (2016) XIA intelligente architektur 04-96/ S. 16

Sigmund B. (2015) SpacerFabric-Pavilion: Textile Leichtbauhülle Detail Research online http://www.detail.de/artikel/spacerfabric-pavilion-textile-leichtbauhuelle-26636/

K.Schäfer, S. Valentin, B. Meier, I Roth, & F. Helbig (2014) „Verbundvergleich von hart mit weich“ Kettenwirk-Praxis Sonderdruck

Schäfer K., Jentzsch H.,& Prof. Helbig (2016) Hybride, textilbasierte Sandwichstrukturen: Herstellung und Charalkterisierung pp 264-271, retrieved from 15th Chemnitzer Textiltechnik-Tagung Tagungsband

Trölitzsch J., Mehrkens M., Loypetch N., Helbig F., & Kroll L. (2016) Herstellung faserverstärkter Sanwichverbunde durch Thermoplast-Schaumspritzgießen pp 272-278, retrieved from 15th Chemnitzer Textiltechnik-Tagung Tagungsband

Bauder H-J., Wolfrum J., & Gresser G. (2015) Entwicklung von textilen Mehrlagenstrukturen mit optimierten Fachwerkkonstruktionen