Downloads

DOI:

https://doi.org/10.7480/jfde.2017.1.1426Published

Issue

Section

License

Copyright (c) 2017 David Appelfeld

This work is licensed under a Creative Commons Attribution 4.0 International License.

Authors or their institutions retain copyright to their publications without restrictions.

How to Cite

Keywords:

Aerogel, Building Insulation Blanket, Façade Thermal Breaks, High Performance Façade, Energy Efficiency, Curtain Wall Thermal OptimizationAbstract

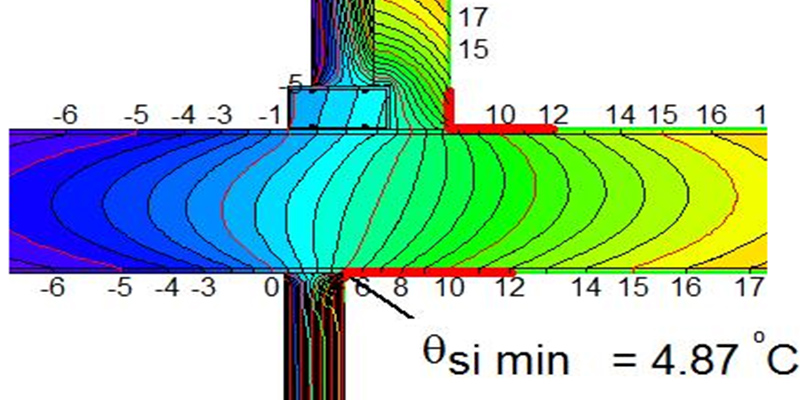

The paper illustrates the use of aerogel technology in façades to reduce thermal bridging and limit condensation. Additionally by mitigating local thermal bridges the indoor climate, especially draught and molds creation, can be eliminated as the surface temperature increases and prevents these negative factors. Curtain walls, in comparison to opaque wall, are often not designed in an energy efficient way and can be large contributors to heat loss of buildings. This is common for curtain walls in Asia and North America, where the energy requirements are not as demanding as in Europe. Building envelopes have many details which can easily introduce thermal bridge due to limited space of insulation or incorrectly solved construction detail. The heat flow through a poor thermally-performing detail, e.g. exposed concrete slab, could account for over 40% of the heat loss of the façade. The contribution of a well-insulated slab could be less than 10%. Unfortunately, traditional insulation techniques are often not suitable due to limited installation space. This paper discusses several case studies whereby the performance of a reference case is compared to a case with a thermally optimized façade implementing Building Insulation Blanket (BIB), which uses silica based aerogel technology. The thermal conductivity of BIB can be as low as 0.015W/mK, and together with its high flexibility and fire resistance enables new design possibilities. The use of BIB in the case studies, contributed to the reduction of overall curtain wall thermal transmittance up to 30%. Additionally condensation risk was significantly reduced.

References

Aegerter, M. A., Leventis, N., Koebel, M. M. (2011) Handbook of Aerogel. Hardcover ISBN978-1-4419-7477-8.

Brunner, S., Wernery, J., Koebel, M. (2015). High Performance Thermal Insulation - Examples From the Swiss Built Environment. CISBAT 2015 - Lausanne, Switzerland, September 9-11, 2015, pp. 39-44.

Casini, M. (2016). Smart Buildings - Advanced Materials and Nanotechnology to Improve Energy-Efficiency and Environmental Performance, Chapter Advanced insulation materials, Woodhead Publishing 2016, ISBN:978-0-08-100972-7.

Dow Corning (2014). Dow Corning® HPI-1000Building Insulation Blanket, Thin-profile, flexible, high thermal re-sistance blanket, Form No. 62-1728B-01.

EN ISO 10077-2 (2012). Thermal Performance of Windows, Doors and Shutters-Calculation of Thermal Transmit-tance, Part 2: Numerical Method for Frames, European Committee for Standardization, Brussels, Belgium, 2012.

EN ISO 12631 (2012). - Thermal performance of curtain walling - Calculation of thermal transmittance, European Committee for Standardization, Brussels, Belgium, 2003.

Flixo Pro, simulation software, http://www.infomind.ch.

IEA (2014), Technology Roadmap Energy Efficient Building Envelopes, 2014.

ISO 10211 (2007). Thermal bridges in building construction - Heat flows and surface temperatures, European Committee for Standardization, Brussels, Belgium, 2007.

ISO 15099 (2012). Thermal performance of windows, doors and shading devices -- Detailed calculations, European Committee for Standardization, Brussels, Belgium, 2003.

Koebel, M., Rigacci, A. & Achard, P. J. (2012). Aerogel-based thermal superinsulation: an overview, Sol-Gel Sci Technol (2012) 63: 315. doi:10.1007/s10971-012-2792-9.

Lawton, M., & Norris, N. (2013). Thermal Bridging: Ignorance is not Bliss, Journal of Building Enclosure Design, Winter 2013.

Mitchell, R., Kohler, C., Arasteh D. (2006). THERM 5.2/WINDOW 5.2 NFRC Simulation Manual, Lawrence Berke-ley National Laboratory, University of California, Berkeley, CA, 2006.

NFRC 100 (2004). Procedure for Determining Fenestration Product U-Factors, National Fenestration Rating Council.

ORNL (2012). Energy Savings Potential of Building Envelope and Windows Technologies, for U.S. Department of Energy, sub-contract ORNL-4000106215 of ORNL, Winbuild Inc., Fairfax, Virginia, 2012.