Downloads

DOI:

https://doi.org/10.7480/jfde.2019.1.2662Published

Issue

Section

License

Copyright (c) 2019 Jungwon Yoon

This work is licensed under a Creative Commons Attribution 4.0 International License.

Authors or their institutions retain copyright to their publications without restrictions.

How to Cite

Keywords:

thermo-responsive, building skin, shape memory polymer (SMP), 3d printingAbstract

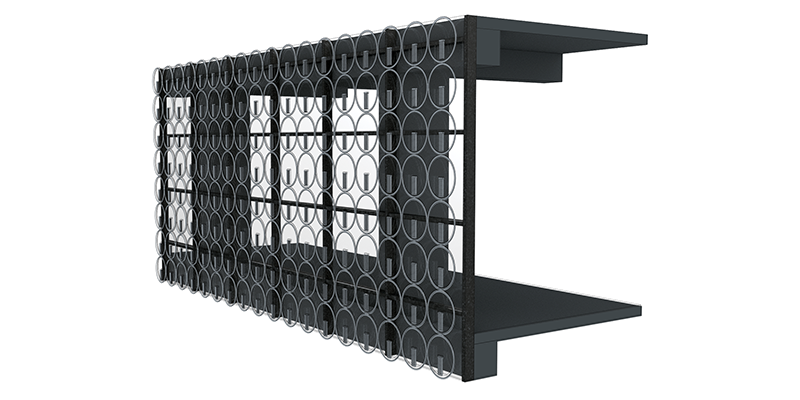

The aim to attain sustainability in the built environment introduced the innovative application of advanced material technologies for low-energy, but aesthetically intriguing, building design strategies. Adaptive and responsive building skins as embedded and intrinsic control systems can be delivered with smart materials, and thus have the potential to minimise the energy consumption of buildings by maximising the natural and passive adjustment of façade components for shading, air-flow, daylight, and view. The dynamic smart material façade, adaptable to changing outdoor environments, is considered to be a holistic design approach that integrates the behavioural performance effects with the appearance and aesthetics of kinetic ability provided by smart materials acting as actuators, by adjusting their properties according to external stimuli. Of the various environmental inputs sensed by, and actuating, active and dynamic building façade systems, this research focuses on temperature as the stimulus to activate a dynamic shading device with the mechanism of opening and closing, specifically considering Seoul’s climate. Among currently available thermo-responsive smart materials, the shape memory polymer (SMP) is investigated as an activator of shading devices to be implemented to adaptive building skin strategies. As the first stage of SMP prototype design and fabrication study toward the thermo-responsive building façade elements, SMP prototypes are proposed in cell types. Among the general thermo-mechanical cycle of thermo-responsive SMP, only programming of the permanent shape via additive manufacturing and recovery at the activation temperature are focused upon in this research. This study proposes a design-to-fabrication workflow integrating computational tools, 3d printing and recalibration of relevant variables in digital design process, G code generation, and manufacturing using commercially available SMP filaments. To verify the 3d printing process, and to demonstrate the shape-changing behaviour of SMP actuators, reproduction of a referenced prototype was conducted, in addition to fabrication experiments of SMP surfaces with various thicknesses and SMP hinges with customised rotating angles. In addition, a base-line prototype combining the static ABS plate and the active SMP hinge is developed to set up the heat test and a digital motion simulation from data of shape changing behaviour acquired from a hands-on model test. After the demonstration of the baseline prototype in design and additive manufacturing process, various SMP prototypes were designed with reference to kinetic prototype researches, but with the consistent 100mm-diameter circular surface, in a scale of 1:3. They were also fabricated with a 3d printer for both open and closed positions to testify to their constructability, and thus to comparatively evaluate the design and fabrication outcomes. Furthermore, after conducting radiation and thermal simulation analysis, shading performance validation is noted for selecting potential prototypes. Lastly, the needs to further develop reversible reiterative shape-changing materials or systems are briefly discussed.

References

Abdelmohsen, S., Adraenssens, S., El-Dabaa, R., Gabriele, S., Olivieri, L., & Teresi, L. (2018). A multi-physics approach for modeling hygroscopic behavior in wood low-tech architectural adaptive systems. Computer-Aided Design, 106, 43-53. https://doi.org/10.1016/j.cad.2018.07.005

Addington, M., & Schodek, D. (2005). Smart Materials and New Technologies - For architecture and design professions. New York, USA: Routledge.

Al-Obaidi, K. M., Azzam Ismail, M., Hussein, H., & Abdul Rahman, A. M. (2017). Biomimetic building skins: An adaptive approach. Renewable and Sustainable Energy Reviews, 79(June), 1472–1491. https://doi.org/10.1016/j.rser.2017.05.028

Arun, D. I., Chakravarthy, P., Arochiakumar, R., & Santhosh, B. (2018). 5.5 Comparison of SMPs and SMAs. Shape Memory Materials. Boca Raton, USA: CRC Press, 50.

Bae, S., Choi, S., & Yoon, J. (2018). A Study of the Influence of 3D Printing Infill Densities on SMP Shape Recovery Behaviors. Submitted for Autumn Annual Conference of AIK(Architectural Institute of Korea), 2018.

Beites, S. (2013). Morphological Behavior of Shape Memory Polymers toward a deployable, adaptive architecture. ACADIA 2013 Adaptive Archiecture, 121-128.

Bengisu, M., & Ferrara, M. (2018). Materials that Move, PoliMI Springer Briefs. https://doi.org/10.1007/978-3-319-76889-2_5

Boldini, A., Colangelo, M., Pilla, A., Tavanti, M., & Mariani, S. (2017). Metereosensitive user-controllable skin for dynamic façades. In 12th Conference on Advanced Building Skins (pp. 740–832). Bern: Advanced Building Skins GmbH.

Clifford, D., Zupan, R., Brigham, J., Beblo, R., Whittock, M., & Davis, N. (2017). Application of the dynamic characteristics of shape-memory polymers to climate adaptive building façades. In 12th Conference of Advanced Building Skins (pp. 171–178). Bern: Advanced Building Skins GmbH.

Coelho, M., & Zigelbaum, J. (2011). Shape-changing interfaces. Personal and Ubiquitous Computing, 15(2), 161–173. https://doi.org/10.1007/s00779-010-0311-y

Erkeçoglu, S., Sezer, A. D., & Bucak, S. (2016). Smart Delivery Systems with Shape Memory and Self-Folding Polymers. In Smart Drug Delivery System. InTech. https://doi.org/10.5772/62199

Fiorito, F., Sauchelli, M., Arroyo, D., Pesenti, M., Imperadori, M., Masera, G., & Ranzi, G. (2016). Shape morphing solar shadings: A review. Renewable and Sustainable Energy Reviews, 55, 863–884. https://doi.org/10.1016/j.rser.2015.10.086

Ge, Q., Sakhaei, A.H., Lee, H., Dunn, C.K., Fang, N.X., & Dunn, M.L. (2016). Multimaterial 4D printing with tailorable shape memory polymers. Scientific Reports 6: 31110. https://doi.org/10.1038/srep31110

Gibson, L. J., & Ashby, M. F. (1997). Cellular Solids: Structure and Properties (2nd edition). Cambridge: Cambridge University Press.

Huang, W., Ding, Z., Wang, C., Zhao, Y., & Purnawali, H. (2010). Shape Memory Materials. Materials Today, 13(7–8), 54–61.

Lelieveld, C.M.J.L. (2013). Smart materials for the realization of an adaptive building component. (Doctoral Thesis). Delft: Delft University of Technology.

Leng, J., Lan, X., Liu, Y., & Du, S. (2011). Shape-memory polymers and their composites: Stimulus methods and applications. Progress in Materials Science, 56(7), 1077–1135. https://doi.org/10.1016/j.pmatsci.2011.03.001

Li, W., Liu, Y., & Leng, J. (2014). Shape memory polymer nanocomposite with multi-stimuli response and two-way reversible shape memory behavior. RSC Advances, 4(106), 61847–61854. https://doi.org/10.1039/c4ra10716k

Lim, J.H., & Yun, G.Y. (2017). Cooling energy implications of occupant factor in buildings under climate change. Sustainability 2017, 9, 2039. https://doi.org/10.3390/su9112039

López, M., Rubio, R., Martín, S., & Ben Croxford. (2017). How plants inspire façades. From plants to architecture: Biomimetic principles for the development of adaptive architectural envelopes. Renewable and Sustainable Energy Reviews, 67, 692–703. https://doi.org/10.1016/j.rser.2016.09.018

López, M., Rubio, R., Martín, S., Croxford, B., & Jackson, R. (2015). Active materials for adaptive architectural envelopes based on plant adaptation principles. Journal of Façade Design and Engineering, 3(1), 27–38. https://doi.org/10.3233/FDE-150026

Lurie-Luke, E. (2014). Product and technology innovation: What can biomimicry inspire? Biotechnology Advances, 32(8), 1494–1505. https://doi.org/10.1016/j.biotechadv.2014.10.002.

Merla, M., Diaferia, R., & Dibari, G. (2016). Application of parametric study and generative algorithms to optimize building physics analyses. In P. LaRoche & M. Schiler (Eds.), PLEA 2016 32nd International Conference on Passive and Low Energy Architecture (Vol. I, pp. 23–28). Los Angeles, California.

Mungenast, M. (2017). Future Façades – Development of 3d-printed Functional-Geometries for Building Envelopes, January 19th 2017-Munich Powerskin Conference Proceedings, 307–317.

Naboni, R., Kunic, A., Breseghello, L., & Paoletti, I. (2017). Load-responsive cellular envelopes with additive manufacturing. Journal of Façade Design and Engineering, 5(1), 37–49. https://doi.org/10.7480/jfde.2017.1.1427

Ning, X., Wang, X., Zhang, Y., Yu, X., Choi, D., Zheng, N., & Rogers, J. A. (2018). Assembly of Advanced Materials into 3D Functional Structures by Methods Inspired by Origami and Kirigami: A Review. Advanced Materials Interfaces, (February). https://doi.org/10.1002/admi.201800284

Ratna, D., & Karger-Kocsis, J. (2008). Recent advances in shape memory polmers and composites: a review. Journal of Material Science, 43, 254-269. https://doi.org/10.1007/s10853-007-2176-7

SMP Technologies (n.d). Shape Memory Polymer Product Info. Retrieved June 26, 2018, from http://www2.smptechno.com/en/smp/

Wang, K., Jia, Y. G., & Zhu, X. X. (2017). Two-Way Reversible Shape Memory Polymers Made of Cross-Linked Cocrystallizable Random Copolymers with Tunable Actuation Temperatures. Macromolecules, 50(21), 8570–8579. https://doi.org/10.1021/acs.macromol.7b01815

Yang, Y., Chen, Y., Wei, Y., & Li, Y. (2016). 3D printing of shape memory polymer for functional part fabrication. International Journal of Advanced Manufacturing Technology, 84(9–12), 2079–2095. https://doi.org/10.1007/s00170-015-7843-2

Yoon, J. (2018). Climate-adaptive Façade Design with Smart Materials: evaluation and strategies of thermo-responsive smart material applications for building skins in Seoul. Submitted for PLEA 2018 HONG KONG: smart and healthy within the 2-degree limit (unpublished).

Yun, G.Y., Kong, H.J., & Kim, J.T.(2012). The effect of seasons and prevailing environments on adaptive comfort temperatures in open plan offices. Indoor and built environment, 2(1), 41-27.

Zhao, Q., Qi, H. J., & Xie, T. (2015). Recent progress in shape memory polymer: New behavior, enabling materials, and mechanistic understanding. Progress in Polymer Science, 49–50, 79–120. https://doi.org/10.1016/j.progpolymsci.2015.04.001.