Downloads

DOI:

https://doi.org/10.7480/jfde.2020.1.4725Published

Issue

Section

License

This work is licensed under a Creative Commons Attribution 4.0 International License.

Authors or their institutions retain copyright to their publications without restrictions.

How to Cite

Keywords:

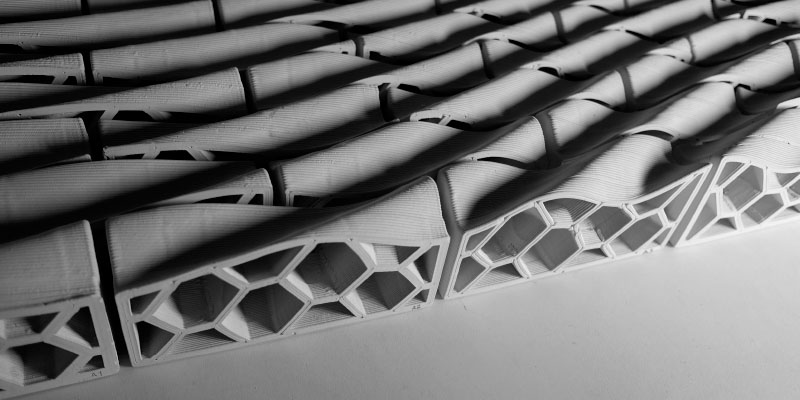

Additive manufacturing, 3D-printing, digital fabrication, ceramic components, façade constructionAbstract

Additive Manufacturing (AM) opens new fields of research and development in the architectural design and construction industry, enabling a geometric freedom that can result in the design of components with specific requirements and multifunctional behaviours.

This work explores the integration of digital design tools and AM extrusion processes on the production of ceramic architectural components for façade construction, reshaping and expanding the boundaries of what is possible to achieve with masonry construction in a wide range of applications (opaque walls, ventilated sunscreens, and shading systems).

Several stoneware prototypes were developed, encompassing different challenges such as the morphology customisation, the versatility of use, the exploitation of the maximum degree of curvature, and the optimisation of structural patterns.

References

Bechthold, M., Kane, A. & King, N. (2015). Ceramic Material Systems: in Architecture and Interior Design,

Birkhäuser, Verlag GmbH, Basel, ISBN 978-3-03821-843-2.

Bergdoll, B. & Massey, J. (2011). Marcel Breuer and Postwar America: Drawings from the Marcel Breuer Papers.

Syracuse: Syracuse University School of Architecture.

Boëthius, J. (2019). Same, Same but Different - learning from references when designing contemporary brick architecture. (Master’s thesis). Chalmers School of Architecture, Gothenburg.

Carpo, M. (2019). The Age of Computational Brutalism. Robotic Building: Architecture in the Age of Automation (1st ed), (pp. 8–9). Munich: Detail Business Information GmbH.

Castañeda, E., Lauret, B., Lirola, J.M., & Ovando, G. (2015). Free-form architectural envelopes: Digital processes opportunities of industrial production at a reasonable price. Journal of Façade Design and Engineering, 3(1), 1-13. doi:10.7480/jfde.2015.1.914

Cruz, P.J.S., Camões, A., Figueiredo, B., Ribeiro, M.J., & Renault, J. (2019). Additive manufacturing effect on the mechanical behaviour of architectural stoneware bricks. Construction & Building Materials, 238, Elsevier. doi:10.1016/j.conbuildmat.2019.117690

Cruz, P.J.S., Knaack, U., Figueiredo, B., & Witte, D. De. (2017). Ceramic 3D printing – The Future of Brick in Architecture. Proceedings of the IASS Annual Symposium 2017, IASS 2017 – Interfaces: Architecture. Engineering. Science. Hamburg: HafenCity University.

Da Silva, A.L., Feltrin, J., Dal Bó, M., Bernardin, A.M., & Hotza, D. (2014). Effect of reduction of thickness on microstructure and properties of porcelain stoneware tiles. Ceramics International, 40(9), Part B, 14693–14699.

Dieste, E. (1996). Reinforced Masonry. Eladio Dieste 1943-1996, Jiménez Torrecillas A. (ed), Seville, Consejería de Obras Públicas y Transportes.

Gualtieri, M.L., Mugoni, C., Guandalini, S., Cattini. A., Mazzini, D., Alboni, C., & Siligardi, C. (2018). Glass recycling in the production of low-temperature stoneware tiles. Journal of Cleaner Production, Vol 197, Part 1, 1531–1539.

Guilherme, P., Ribeiro, M.J., & Labrincha, J.A. (2009). Behaviour of different industrial ceramic pastes in the extrusion process. Advances in Applied Ceramics, 108(6), 347–351.

Gültekina, E.E., Topateşb, G., & Kuramac, S. (2017). The effects of sintering temperature on phase and pore evolution in porcelain tiles. Ceramics International, 43(14), 11511–11515.

Khoshnevis, B. (2004). Automated construction by contour crafting-related robotics and information technologies. Automation in Construction, 13(1), 5-19. doi:10.1016/j.autcon.2003.08.012

Martín-Márquez, J., Rincón, J.M., & Romero, M. (2008). Effect of firing temperature on sintering of porcelain stoneware tiles. Ceramics International, 34(8), 1867–1873.

Mitchell, W. & McCullough, M. (1997). Digital Design Media. New York: John Wiley & Sons, Inc.

Oummadi, S., Nait-Ali, B., Alzina, A., Victor, J.-L., Launay, Y., Mirdrikvand, M., Dreher, W., Rezwan, K., & Smith, D.S. (2019). Distribution of water in ceramic green bodies during drying, J. Eur. Ceram. Soc., 39, 3164–3172.

Pallasma, J. (1998). Alvar Aalto: Toward a Synthetic Functionalism. AlvarAalto: Between Humanism and Materialism, Peter Reed (Ed.). New York: The Museum of Modern Art.

Park, J. & Baldanchoijil, G. (2014). The Superimposition of Circles Cut into Louis I. Kahn′s Building Façades, Journal of Asian Architecture and Building Engineering, 13(2), 389-396. DOI: 10.3130/jaabe.13.389

Peters, B. (2014). Building Bytes: 3D-Printed bricks. Fabricate 2014: Negotiating Design Making, Zurich: gta Verlag.

Pfefferkorn, K. (1924). Ein Beitrag zur Bestimmung der Plastizität in Tonen und Kaolinen. Sprechsaal [A contribution to the determination of plasticity in clays and kaolins], 57(25), 297–299.

Rael, R., & San Fratello, V. (2018). Printing Architecture: Innovative Recipes for 3D Printing. Princeton Architectural Press.

Rambaldi, E., Pabst, W., Gregorová, E., Prete, F., & Bignozzi, M.C. (2017). Elastic properties of porous porcelain stoneware tile. Ceramics International, 43(9), 6919–6924.

Ramcke, R. (2001). Masonry in architecture. Masonry construction manual. Gerd Soffker; Philip Thrift, Elizabeth Schwaiger (Eds.). Basel; Boston; Berlin: Birkhauser; Munich: Ed. Detail. (pp. 8-52).

Ribeiro, M.J., Blackburn, S., & Labrincha, J.A. (2009). Single screw extrusion of mullite-based tubes containing Al-rich anodising sludge, Ceramics International, 35(3), 1095–1101.

Ribeiro, M.J., Ferreira, J.M., & Labrincha, J.A. (2005). Plastic behaviour of different ceramic pastes processed by extrusion. Ceramics International, 31(4), 515–519.

Ribeiro, S. (2020). Optimization of ceramic pastes for extrusion processes by additive manufacturing and respective characterization of mechanical behaviour, (Master’s thesis). University of Minho, Portugal (in Portuguese).

Sabin, J.E., Miller, M., Cassab, N., & Lucia, A. (2014). PolyBrick: Variegated Additive Ceramic Component Manufacturing. ACCM 3D Printing and Additive Manufacturing, 1(2), 78–84. https://doi.org/10.1089/3dp.2014.0012, 2015.

Sampaio, A.M., Gonçalves, R., Lima, R., Cruz, P.J.S., Figueiredo, B., Carvalho, S., & Pontes, A.J. (2019). Design for Additive Manufacturing of Mechanical Connections Toward Hybrid Products, Advances in Additive Manufacturing, Modeling Systems and 3D Prototyping, Proceedings of the AHFE 2019 International Conference on Additive Manufacturing, Modeling Systems and 3D Prototyping, July 24–28, Washington D.C., USA. Springer Nature Switzerland AG 2020, M. Di Nicolantonio et al. (Eds.): AHFE 2019, AISC 975, pp. 418–427.

Sarakinioti, M-V., Konstantinou, T., Turrin, M., Tenpierik, M., Loonen, R., Klijn-Chevalerias, M. L., & Knaack, U. (2020). Development and prototyping of an integrated 3D-printed façade for thermal regulation in complex geometries. Journal of Façade Design and Engineering, 6(2), 029-040. doi:10.7480/jfde.2018.2.2081

World Economic Forum (2016). Shaping the Future of Construction - A Breakthrough in Mindset and Technology, Industry Agenda, Ref. 220416, Prepared in collaboration with The Boston Consulting Group. Switzerland: World Economic Forum.