Downloads

DOI:

https://doi.org/10.7480/jfde.2015.3-4.875Published

Issue

Section

License

Copyright (c) 2016 Holger Strauss, Ulrich Knaack

This work is licensed under a Creative Commons Attribution 4.0 International License.

Authors or their institutions retain copyright to their publications without restrictions.

How to Cite

Keywords:

Architecture, facade engineering, 3D printing, Additive Manufacturing, bespoke building envelopes, future facades, innovation, performance, file to factoryAbstract

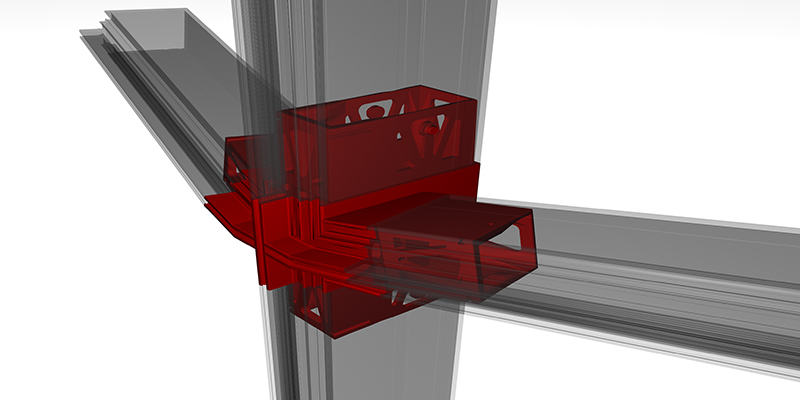

The basic principle of ‘3D Printing’ is the layer wise production of real parts from virtual data – be it with laser, with power glue, electron beam or UV light processing (Hopkinson, Hague, & Dickens, 2006). The professional application of ‘3D Printing’ is ‘Additive Manufacturing’ (AM) and this opens a fascinating new world of engineering. It offers a selection of reliable building construction materials – done in concrete, aluminium, steel, high performance plastics or glass. (Woodcock, 2011) No matter what applications can be found: to ‘design for function’ rather to ‘design for production’ turns our way of engineering of the last century upside down. As a result, AM opens the outlook to applications in our (built) future in combination with the available technologies of today. (Strauß, 2013)

The tool-less production with AM allows for new shapes and functional parts in small batch sizes – down to batch size one. The parts performance can be re-interpreted based on the demands within the system, not based on the limitations of conventional manufacturing. AM offers new ways of materializing the physical part around its function. Advancements can for example be achieved in the semi-finished goods: fittings with less, but higher integrated parts could offer a better performance with lower material consumption. Solving the most critical part of a free-form structure and allowing for a smart combination with the approved standards has a great potential, as well. It leads toward customized and enhanced performance.

This paper discusses the possible changes and influences, those emerging technologies have on the development of building envelopes. To achieve today’s demands of future envelopes, we have to find new solutions - Additive Manufacturing is one possible way to do so.

References

Burns, M. (1999 -2003). fabbers.com, 2012, from http://www.ennex.com/%7Efabbers/

Christensen, A. (2014). Changing the game in Healthcare. tct magazin, 82.

Davidson, S. (2012). Grasshopper - Generative Modeling for Rhino, 2012, from http://www.grasshopper3d.com/

Davies, M. (1981). A Wall For All Seasons. RIBA Journal, 2(88).

DUSarchitects. (2015). 3D Print Canal House Retrieved 31.03.2015, 2015, from http://3dprintcanalhouse.com/kamermaker-1

Gausemeier, J. (2013). Evaluation of the expert survey on the Future Relevance of Additive Manufacturing Research. Paderborn, Germany: DMRC, Heinz Nixdorf Institute, University of Paderborn.

Hees, K.-M. (2013, 20. September 2013). [Research Director Europe. Kawneer-Alcoa].

Hopkinson, N., Hague, R. J. M., & Dickens, P. M. (2006). Rapid Manufacturing. An Industrial Revolution for the Digital Age. Chichister, England: John Wiley and Sons, Ltd.

Khoshnevis, B. (2006). Contour Crafting, from http://www.contourcrafting.org/

MaterialsViews. (2013). Entering an new dimension: 4-D printing. Materials Views Newsletter Retrieved October, 2013, from http://www.materialsviews.com/entering-a-new-dimension-4-d-printing/

Nike. (2015). nikeid Retrieved 31.03.2015, 2015, from http://www.nike.com/de/de_de/c/nikeid

Piller, F. T. (2012). Mass Customization & Open Innovation - A Blog by Frank T. Piller Retrieved April, 2012, from http://mass-customization.de/

Rammig, L. (2010). Direct Glass Fabrication - New Applications of glass with additive processes. M.Eng. Masterthesis, Hochschule OWL - University of Applied Sciences, Detmold.

Rieder, A. (2013). fibreC - 3D fassade Retrieved September 2013, 2013, from http://www.rieder.cc/at/de/main/referenzen/reference/19/

Sandhana, L. (2013). The room with 260 million surfaces: 3D printed architecture is here. gizmag online newsletter. Retrieved from www.gizmag.com website: http://www.gizmag.com/swiss-architects-3dprint-a-room/29299/

Strauß, H. (2008). Funktionales Konstruieren - Einfluss additiver Verfahren auf Baukonstruktion und Architektur. Dipl.-Ing., Hochschule OWL, Detmold.

Strauß, H. (2010). AM Facades - Influence of additive processes on the development of facade constructions. Final Report of research project. Hochschule OWL - University of Applied Sciences. Detmold.

Strauß, H. (2013). AM Envelope - The potential of Additive Manufacturing for facade construction. Dr.-Ing., Delft University of Technology, Delft. (AB+E, 01/2013)

Ulrich Knaack, M. B., Holger Strauß. (2010). Rapids - Layered Fabrication Technologies for Facades and Building Construction (Vol. 04). Rotterdam: 010 Publishers.

VolkswagenAG. (2015). Konfigurator von Volkswagen.de Retrieved 31.03.2015, 2015, from http://app.volkswagen.de/ihdcc/de/configurator.html

Voxeljet. (2015). VX4000: das großformatige 3D-Drucksystem Retrieved 31.03.2015, 2015, from http://www.voxeljet.de/systems/vx4000/

Whadhock, I. (2012). A third industrial revolution. The Economist. Retrieved from http://www.economist.com/node/21552901

Woodcock, J. (2011). Living in a (Multi) Material World - Objet Focus on Democratizing Multi-Materials Process and new functional materials. tct magazin.