Downloads

DOI:

https://doi.org/10.7480/jfde.2016.1-2.1114Published

Issue

Section

License

Copyright (c) 2016 Urs Mueller

This work is licensed under a Creative Commons Attribution 4.0 International License.

Authors or their institutions retain copyright to their publications without restrictions.

How to Cite

Keywords:

Façade, reactive powder concrete, textile reinforcement, durability, strengthAbstract

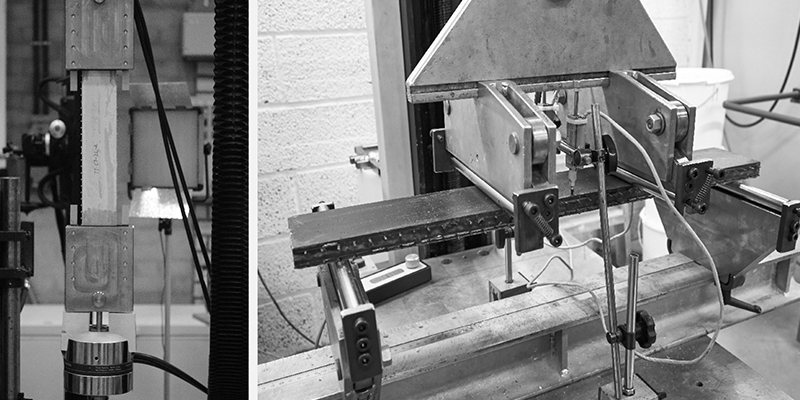

Reactive powder concrete (RPC) is a fairly novel material with extraordinary strength and durability properties. Due to these properties, it is increasingly being utilized for external facade cladding thus enabling a considerable reduction in the thickness of concrete elements. Commercial RPC formulations on the market are usually expensive and less sustainable due to high cement clinker contents. In this study, improved RPC formulations with higher amounts of supplementary cementitious materials (SCMs) were developed. The formulations were combined with different types of reinforcements ranging from steel fibres to fibre textile grids primarily to enhance the ductility and tensile strength of the material.

The results showed that even with clinker replacement levels of up to ca. 40 % of the total binder amount, a satisfactory mechanical performance of the RPC mixes could still be achieved. A fairly steep strength gain rendered heat treatment unnecessary. The materials displayed good flow properties and a reasonably short initial setting time. The incorporation of carbon textile fibre grids proved to be highly effective in improving the post failure performance of the RPC. The results validated a more sustainable approach for RPC applied to thin facade elements..References

Andrade, C. (2009). Reinforcement corrosion: Research needs. Concrete Repair, Rehabilitation and Retrofitting II, ISBN 978-0, 81–88.

Andreasen, A. H. M. (1930). Über die Beziehung zwischen Kornabstufung und Zwischenraum in Produkten aus losen Körnern (mit einigen Experimenten). Kolloid-Zeitschrift, 50(3), 217–228.

CEN/TS 12390-9. Testing hardened concrete - Part 9: Freeze-thaw resistance - Scaling (2006).

de Larrard, F., & Sedran, T. (1994). Optimization of ultra-high-performance concrete by the use of a packing model. Cement and Concrete Research, 24(6), 997–1009.

Elkem Materials Mixture Analyser – EMMA. (n.d.). Retrieved from https://www.elkem.com/download-centre/?query=emma&tags=Refractories&cat=

EN 206-1. Concrete - Specification, performance, production and conformity. (2013).

Engberts, E. (2006). Large-size facade Elements of textile reinforced concrete. In 1st International RILEM Conference on Textile Reinforced Concrete (pp. 309–318). RILEM Publications SARL.

Ghoneim, G., El-Hacha, R., Carson, G., & Zakariasen, D. (2010). Precast Ultra High Perfromance Fibre Reinforced Concrete Replaces Stone And Granite On Building Façade. In Proceedings of the 3rd fib International Congress – 2010 (pp. 1–15).

Hegger, J., Horstmann, M., & Scholzen, A. (2008). Sandwich Panels with Thin-Walled Textile-Reinforced Concrete Facings. In C.-M. Aldea (Ed.), Design and Applications of Textile Reinforced Concrete (pp. 109–123). American Concrete Institute.

Hegger, J., & Voss, S. (2008). Investigations on the bearing behaviour and application potential of textile reinforced concrete. Engineering Structures, 30(7), 2050–2056.

Heinz, D., Urbonas, L., & Dehn, F. (2004). Fire resistance of ultra high performance concrete (UHPC) - Testing of laboratory samples and columns under load. In M. Schmidt, E. Fehling, & C. Geisenhanslüke (Eds.), International Symposium on Ultra High Performance Concrete (pp. 703–715). Kassel: Kassel University Press.

Müller, C. (2006). Production and Application of Blended Cements.

Müller, U., Lehmann, C., Fontana, P., & Meng, B. (2009). Effects of autoclaving on the nano structure and phase composition of Ultra High Performance Concrete. In B. Middendorf, A. Just, D. Klein, A. Glaubitt, & J. Simon (Eds.), 12th Euroseminar on Microscopy Applied to Building Materials (pp. 351–359). Dortmund: Technical University of Dortmund.

Müller, U., Meng, B., Kühne, H.-C., Nemecek, J., Fontana, P., & Fehling, E. (2008). Micro texture and mechanical properties of heat treated and autoclaved Ultra High Performance Concrete (UHPC). In E. Fehling, M. Schmidt, & S. Stürwald (Eds.), 2nd International Symposium on Ultra High Performance Concrete (Heft 10., pp. 213–220). Kassel, Germany: Kassel University Press.

Neville, A. (1983). CORROSION OF REINFORCEMENT. Concrete (London).

NT BUILD 492. Concrete, mortars and cement-based repair materials: Chloride migration coefficient from non-stady-state migration experiments (1999).

Rebentrost, M., Wight, G., & Fehling, E. (2008). Experience and Applications of Ultra-high Performance Concrete in Asia. In E. Fehling, M. Schmidt, & S. Stürwald (Eds.), 2nd International Symposium on Ultra High Performance Concrete (Heft 10., pp. 19–30). Kassel, Germany: Kassel University Press.

RILEM-Method. RILEM TC 232-TDT. Test methods and design of textile reinforced concrete: Uniaxial tensile test – Test method to determine the load bearing behaviour of tensile specimens made of textile reinforced concrete. (2014). RILEM Draft Recommendation.

Schachinger, I., Hilbig, H., Stengel, T., & Fehling, E. (2008). Effect of Curing Temperature at an Early Age on the Long-Term Strength Development of UHPC. In E. Fehling, M. Schmidt, & S. Stürwald (Eds.), 2nd International Symposium on Ultra High Performance Concrete (Heft 10., pp. 205–213). Kassel, Germany: Kassel University Press.

SS 137244. Concrete testing - Hardened concrete - Scaling at freezing (2005).

Stenberg, E. (2013). Structural Systems of the Million Program Era. KTH School of Architecture.

Teichmann, T., & Schmid, M. (2004). Influence of the packing density of fine particles on structure, strength and durability of UHPC. In M. Schmidt, E. Fehling, & C. Geisenhanslüke (Eds.), International Symposium on Ultra High Performance Concrete (pp. 313–323). Kassel: Kassel University Press.